Most enterprises utilize the round bar steel produced from the steel mill as grinding rods. The round steel bar has a low hardness, leading to breaking damage easily and very low wear resistance. The wear resistant effect of the new type of allow steel grinding rods is 150% stronger than the rolled steel bar. Marked by excellent war resistant property, this product will save the customers a lot of money in the future. Manufactured using the latest and greatest technology the dimensions can easily be altered to meet your need. The product can serve the customers for a longer time allowing it to economize the overall grinding production. Moreover, it eliminates the need to stop and add a new grinding rod each and every day, enhancing the overall productivity.

Steel grinding rods have a wear resistance effect that is 150% stronger than that of rolled steel bars.

They have excellent wear-resistant properties

They are strong and more durable

They do not crack and wear out easily.

In grinding media steel rods are used in metallurgy and mining for grinding the ores such as iron, copper and gold. It is used for the processing of extracted minerals.

Rod mills produce less grit and slime, lighter crushing and a product with consistent particle size.

Rod mills are recommended when the finished product size is required to be 1-3mm. If the finished product is less than 0.5mm. It is recommended to use either forged steel balls or cast iron balls.

Grinding rods are another type of grinding media. Unlike forged and cast grinding balls, they are designed for application in rod mills for processing metals like iron, gold, and copper. Alternatively, some of our clients use them for processing coke and friable non-minerals, grinding glass, or grinding gravel to produce sand.

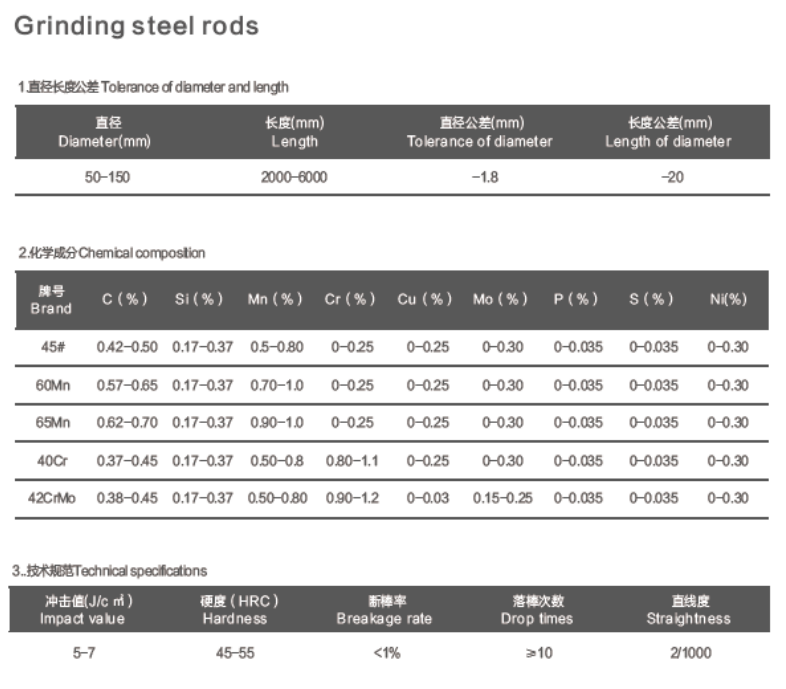

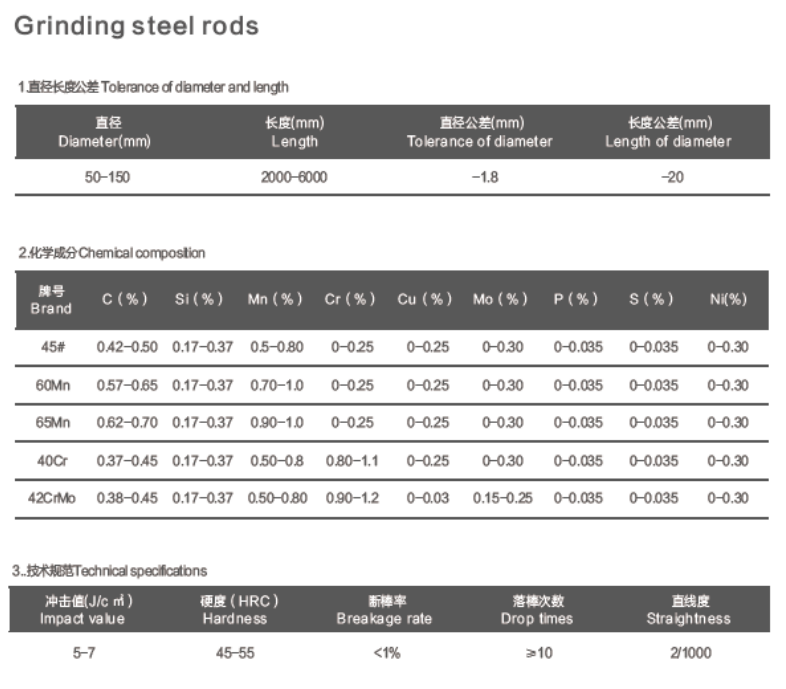

Although we produce round bars in a variety of sizes, our quenching and tempering furnace for grinding rods can heat treat sizes from 50-150mm with maximum length of 6m, based on its design.

As is the case with grinding balls, our heat treatment process for steel rods is also the famous quench temper process. Nevertheless, there are details in the heat treatment process that requires experience and proficiency to maximize wear resistance and milling efficiency. Alpha has a team of heat treatment experts and metallurgists on board who adjust the parameters according to raw material and end-users’ application.

We control the straightness of our rods by a special straightening equipment. Length tolerance and diameter tolerance are according to internationally approved standards. We supply grinding rods in standard packaging of 2-3 MT bundles in 20’ containers. Our grinding rods are the perfect match for the most abrasive milling conditions due to high hardness, low wear rate and toughness.

Steel grinding rods are sold directly, and through the top steel suppliers in China. There are plenty of quality producers of steel solutions in China, formed by hot-rolling processes. These rods are made with special steel and varying alloy to enhance the performance and properties of the rods. They are hardened by micro alloying steel and heat treatments. Manufactured with the best and latest techniques, the dimensions can easily be altered according to the client’s needs

A Grinding rod is an industrial product with multiple uses. The most popular uses of grinding rods are in construction, building material, household appliances, roofing, decoration, and tube making and they are also often used to grind material for glass and grind gravel to produce the sand.

Our customers use grinding rods mainly in metallurgy and mining for grinding the ores such as iron, copper and gold and in processing of extracted minerals as well as for grinding coke and friable non-metals.

Steel grinding rods usually have a wear resistance effect that is 150% stronger than that of rolled steel bars, so rods do not crack and wear out easily.

Our quality and reliable source of steel products and solutions match domestic and foreign demands for varying steel resources. Our international background allows us to operate and provide steel solutions for countries beyond China across Southeast Asia, the Middle East, Africa, and others.

We have immaculate logistic integrity and have years of experience working with suppliers to provide steel grinding rods to diverse customization and processing to meet customer’s various needs. We provides the best cost reduction and can obtain market analysis through experts in the industry taking advantage of the market trends and current value of grinding rods to provide quality and continued expertise in steel trading.

Production of Steel Grinding Rods

Steel grinding rods sold by us receive surface treatment such as galvanization. A majority of these Grinding Rods are used in construction sectors.

In factories, Steel Grinding Rods are made by hot rolling processes. These rods are made with special steel and varying alloy to enhance the performance and properties of the rods. They are hardened by micro alloying steel and heat treatments. Manufactured with the best and latest techniques, the dimensions can easily be altered according to the client’s needs.

Grinding Rods are the optimal choice when strength, resistance and longevity are important to the task.

Highlights and Benefits of Grinding Rods

The following are additional points of interest when considering using Steel Grinding Rods:

● Is corrosion and rust resistant

● Have excellent wear resistant properties

● Is delivered in superior quality materials

● Size and color can be altered according to customers’ needs

Steel Grinding Rods are shipped in bundles of different weights or rod count according to the client’s requirement to any port near you.

Maybe you have tried to import Grinding Rods from China before, but you did not get the best value for your money; or perhaps you have never imported steel and opt for over-priced local suppliers?

We pride ourselves on our business track record, and cost efficient supply chain. We guarantee that you will be satisfied with our services.